Aulbach Automation GmbH abk Pressenbau

Booth number: EG-GP 11

abk-pressenbau.de/

About us

abk Pressenbau stands for durable technology, tailor-made solutions and a deep understanding of the entire deburring process.

Our strength lies in understanding complex requirements and turning them into precise solutions – technically sophisticated and perfectly tailored to each specific application. Thanks to our long-standing consulting expertise, we take into account not only the press itself but also the interaction of all process steps.

We design, engineer and manufacture press systems, automation and control technology entirely in-house – with around 70 dedicated employees at our site in Germany.

Our customers benefit from short decision-making processes, direct communication and close coordination partnership based collaboration. All relevant specialist departments are centrally integrated, enabling us to respond quickly and efficiently, even in demanding projects.

Address

Am Amorbach 3

63853 Mömlingen

Germany

E-mail: info@abk-pressenbau.de

Phone: +49 6022 264760

Internet: abk-pressenbau.de/

Contact person:

Products & Services

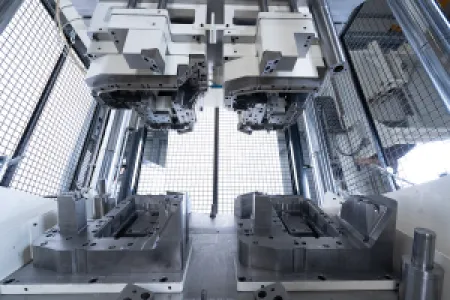

Mega Casting

Tilting table presses

Customized Presses and Equipment

C-Frame Presses

Column Presses

Sliding Tilting Table Press

Spotting Presses

Peripherical Equipment

Tilting Table Presses

The advantages at a glance

The presses are available in all common sizes, from 1300 mm to 2600 mm columns passage and press forces up to 300ton

The abk column guides are without central lubrication – maintenance-free and wear-free.

If necessary, the scrapers can be easily replaced in the assembled state.

Designed for robot automation

Optimal burr removal by turning/tilting the lower table

abk has developed a new rotary drive that requires little maintenance.

The high-performance rotary drive, in the absence of a sliding table drive ensures shorter times in the overall press cycle

Maximum rotation angle of 0° – 180° is drivable

low press space requirements, weight and material savings

the drive power is designed individually, according to the customer’s requirements

Column Presses

All abk presses are designed for low-maintenance operation.

The abk column guides are without central lubrication – maintenance-free and wear-free. The maintenance-free column guidings are also low-friction. This gives customers additional benefit due to energy savings.

The abk column presses enable optimized disposal of burrs, runners and overflows through a large table opening.